AEM Senior VP of Agriculture, Charlie O’Brien, Explains Today’s Farm Equipment Manufacturing Trends and How Manufacturers can Use Data to Inform Field Service and Drive Customer Satisfaction

“It used to be all about the iron. Now it’s all about the data.”

That’s what Senior Vice President of Agriculture at the ” Association of Equipment Manufacturers (AEM), Charlie O’Brien, said during our recent conversation about farm equipment trends. Charlie serves as the face of AEM’s agriculture activities and represents the farm equipment industry on behalf of AEM.

During our conversation, we kept coming back to one theme: ag equipment manufacturers are integrating more sophisticated technology into machines, which is driving data-backed intelligence and service for dealers and hands-on interactions with machines for farmers.

Making Use of Intelligent Machine Data in Agriculture

The influx of data in recent years, said Charlie, represents an evolution in product support. And the evolution [from machine to data] will continue to magnify over the next decade. “We’re just at the cusp of this revolution in terms of utilization of the data and what that means for the ag industry.”

All the data coming off the sensors is revolutionizing the agriculture industry as a whole. And, in the last few years, manufacturers and farmers are discovering how to use it.

“Just a couple years ago, I was talking to some farmers in Illinois about the reams of data coming off combines, etc. They had a lot of data, but didn’t know what to do with it. Now they have the tools that can take that data, put it into a farm management system of some kind, and combine it to inform key decisions that guide the company.”

“In just a few years, the ag industry has gone from mountains of data farmers didn’t know what to do with to intelligent information they can use to inform decisions.”

3 Ways Connected Equipment Drives New Strategies

“Farming is a complex industry. It’s interesting because there’s so much interconnectivity within agriculture. There’s a lot of data coming in from pieces like irrigation equipment, fertilizers, seeders, moisture sensors in the ground, etc., and it’s all connected.”

The trick is to make sure the right data ends up in the right people’s hands so they have the information to make the right decisions. (e.g. agronomist, crop insurance representative, equipment dealer, etc.). Here are some of the main impacts of smart machines in the industry.

1. Reduced Machine Downtime:

The reality is that, for farmers, time is money. It used to be that if something broke down in the field, farmers could wait a couple days to get the piece of equipment fixed. Today, the farm business has sped up just like every other business, so downtime is money. As a result, farmers need to make sure they minimize machine downtime as much as possible. Sharing machine data with service providers significantly reduces downtime for the farmer, while opening up opportunities for additional revenue on the equipment dealer and manufacturer ends.

2. Consolidation of Dealers:

Dealerships are shape-shifting to reflect service needs. Dealers are consolidating and relocating to areas with the greatest service need rather than being placed in certain regions like they used to be. “Based on the data, manufacturers can see which equipment and farming areas have the greatest service needs and set up a dealership near that area.”

3. Smart Farming:

Another example of farmers using data to improve results is through an agronomist who, with the right data, is able to write a prescription based on the conditions, recommending things like time of year to plant, seed variety, and fertilizer type to maximize yields.

Learn more about smart farming in our free Internet of Things guide.

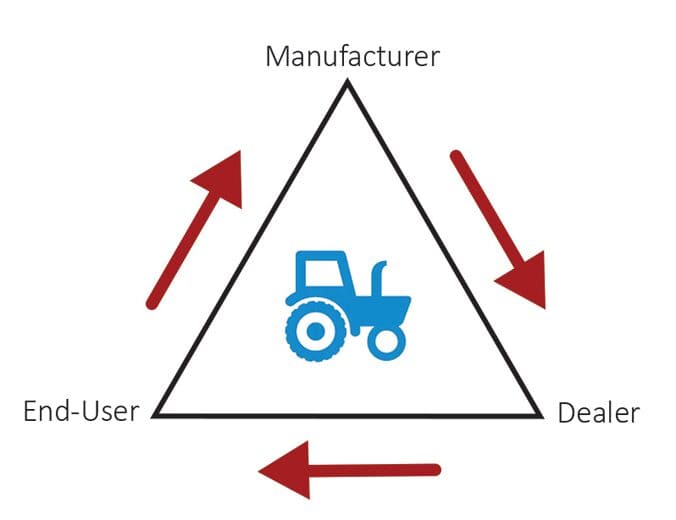

Equipment Triangle Delivers Mutual Benefit for Manufacturer, Dealer, and Farmer

Access to and sharing of equipment data provides benefits at the manufacturer, dealer, and farmer levels.

- Manufacturers

Manufacturers are constantly looking for ways to streamline their organization and increase sales. Specifically, they want to see how their equipment is performing in the field and how operators are using it.

Data coming off machines is helpful to the farmer using the equipment, but it’s also an important resource for manufacturers looking to understand exactly how their equipment is being used, how they can improve feature production, and, perhaps most importantly, how they can create revenue opportunities from product support programs.

“Data coming from equipment can actually send a service truck out to the farm before anything ever happens. It prevents downtime, which if you ask a farmer, downtime basically means money.”

- Dealers

Access to machine data helps dealers meet increasing service requirements of very sophisticated equipment. They gain insight into when equipment needs to be serviced, and use that information to inform proactive preventive maintenance visits.

If all dealers in the network are held to the same service standards and utilize similar machine technology, they’ll offer a more consistent service experience for all customers. With access to resources and data, dealers can build stronger relationships with customers, become their trusted advisors, and prevent unscheduled equipment downtime.

- Farmers

Farmers benefit from access to equipment intelligence, like how long a machine sits idling during a given day. They’re able to gain insight into their own equipment performance data and can rely on more informed dealers to maintain their machines.

Mobile is Changing the Landscape for Both Farmers and Service Providers

Ultimately, customers are asking equipment manufacturers, “how can I be more efficient, make more money, and save myself time?” Mobile technology – for farmers, dealers and manufacturers – is an essential piece in agriculture today.

Farmers used to have to be so hands on in their operation. Now, they can be anywhere. They just pull up an app to see where all the pieces of equipment are, how the equipment is performing overall, whether it’s idle, what the fuel consumption is, etc.

Mobile field service apps are also a key piece in the ag equipment service puzzle. Equipping field techs with a mobile app enables service providers to get paid faster, make informed decisions based on real-time information, schedule more effectively, monitor spare parts and tasks, and keep the team connected.

Conclusion: Mobile and Connected Equipment Drive Efficiency and Equipment Uptime

When it comes to the ag business, everyone’s trying to become more efficient, and advancing mobile and machine technologies are driving increased efficiency. When ag equipment manufacturers make use of the connected and intelligent data available, they can use that information to equip dealers with the best service knowledge and develop more efficient and intelligent products. And, as many manufacturers and farmers are realizing, intelligent, automated equipment brings more precision, convenience and uptime to your operation.

Free Guide: How the Internet of Things is Revolutionizing Field Service