Industrial Field Service Management Software

Industrial Equipment Industry

Industrial equipment distributors, OEMs, and service organizations need specialized solutions for managing pumps, compressors, and manufacturing systems. Service Pro’s industrial field service management software optimizes technician dispatch, maintenance tracking, and service delivery to drive profitability and equipment reliability.

Trusted by leaders

Solve Critical Industrial Service Challenges

Industrial machinery powers manufacturing facilities, processing plants, and production environments where every minute of downtime impacts the bottom line. Service organizations must balance regulatory compliance requirements with the need to minimize equipment failures and maximize operational productivity.

Key differentiators

Why We're Different

What Makes Service Pro the Right Choice for Industrial Service Operations

Specialized for Equipment Service Organizations

Dedicated Field Service Expertise

Flexible Integration Architecture

Fully US-Based Support Team

Specialized for Equipment Service Organizations

Developed specifically for industrial equipment maintenance over 15+ years. We’ve built our platform around the real-world challenges of managing service operations for complex industrial machinery.

Dedicated Field Service Expertise

Unlike all-in-one business platforms, our singular focus on field service technology means continuous innovation that directly benefits your service operations and profitability.

Flexible Integration Architecture

Seamlessly connect with your existing business systems through robust APIs that integrate with Epicor Prophet 21, NetSuite, Microsoft Dynamics Business Central, Sage 100, and other leading ERP platforms.

Fully US-Based Support Team

With over 15 years serving the field service industry exclusively and a completely US-based team, you’ll receive expert support whenever you need assistance.

How We Can Help

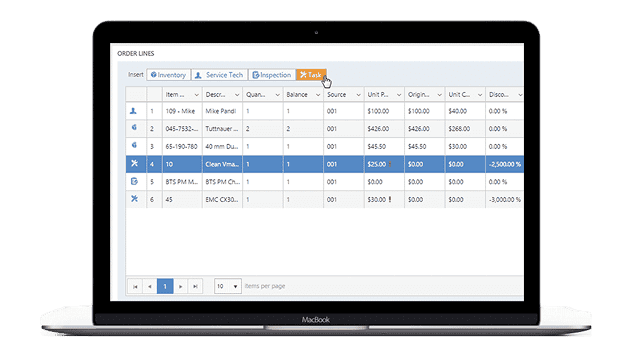

Dispatch Management

Service Contracts

Inventory Control

Equipment History Tracking

Field Technician Mobile Platform

Digital Inspection Workflows

Flexible Form Configuration

Intelligence Reporting

ERP System Integration

Dispatch Management

Streamline technician assignments and optimize routing for industrial service calls

Service Contracts

Automate preventive maintenance scheduling and contract compliance tracking

Inventory Control

Monitor parts inventory in real-time and trigger automatic reordering based on historical usage data for specific equipment types

Equipment History Tracking

Maintain comprehensive records of industrial assets including service history, performance metrics, and warranty information

Field Technician Mobile Platform

Empower technicians with a robust cross-platform mobile app designed for industrial equipment service environments

Digital Inspection Workflows

Execute standardized equipment inspections with customizable checklists, photo documentation, and electronic signature capture

Flexible Form Configuration

Design maintenance forms that align with your operational procedures and industry-specific compliance requirements

Intelligence Reporting

Generate actionable insights through dynamic reports that support compliance documentation and performance analysis

ERP System Integration

Synchronize service data with backend systems including NetSuite, Sage 100, Epicor Prophet 21, and Microsoft Dynamics

The mobile application has been a game-changer, providing technicians with real-time access to job details, customer information, and service history.”